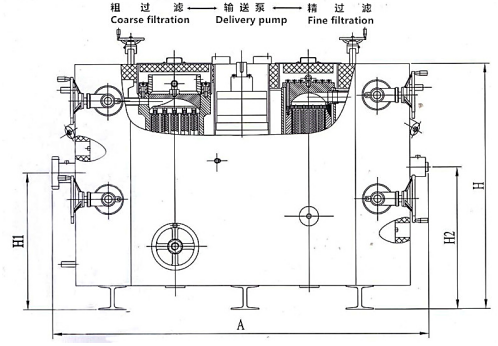

Structure diagram

technical parameter

| model | Pipe diameter (mm) | Filtration area (㎡) | Rated flow (kg / h) | Main structure size | System pressure | Biphenyl jacket pressure | Allowable differential pressure | Operating temperature | |||||

| PET | PP, PE | H | H1 | H2 | A | ||||||||

| CPF-PT4-1.26 / 1.05 | 30 | 1.26 / 1.05 | 100-140 | 140-180 | 1150 | Custom | Custom | Custom | 2200 | Max25Mpa | ≤0.6Mpa | Max6Mpa | ≤310 ℃ |

| CPF-PT4-1.8 / 1.26 | 30 | 1.8 / 1.26 | 130-160 | 160-200 | 1200 | 2200 | |||||||

| CPF-PT4-3.5 / 2.5 | 40 | 3.5 / 2.5 | 200-250 | 250-300 | 1250 | 2300 | |||||||

| CPF-PT4-5.5 / 3.5 | 40 | 5.5 / 3.5 | 260-350 | 320-400 | 1250 | 2400 | |||||||

| CPF-PT4-7.5 / 4.5 | 50 | 7.5 / 4.5 | 400-520 | 550-650 | 1350 | 2500 | |||||||

| CPF-PT4-9.5 / 5.5 | 50 | 9.5 / 5.5 | 500-600 | 650-750 | 1350 | 2600 | |||||||

| CPF-PT4-12 / 7.5 | 50 | 12 / 7.5 | 650-750 | 800-900 | 1500 | 2600 | |||||||

| CPF-PT4-15 / 9.5 | 65 | 15 / 9.5 | 800-1000 | 950-1100 | 1760 | 2650 | |||||||

| CPF-PT4-19 / 12 | 65 | December 19 | 1100-1500 | 1350-1450 | 2080 | 2650 | |||||||

Scope of application:

Recycled materials (PET, PP, PE, etc.) for fine filtration spinning

heating method:

Heat transfer oil electric heating, heat transfer oil circulation heating, static biphenyl heating and biphenyl circulation heating

System advantages:

The melt is filtered through two stages, which can more effectively remove impurities and gel particles in the polymer, improve product quality, and prolong the working cycle of the spinning assembly to a large extent.